Sophisticated buffer handling allows to operate on plain file streams, on sockets, or manually fed buffer content.

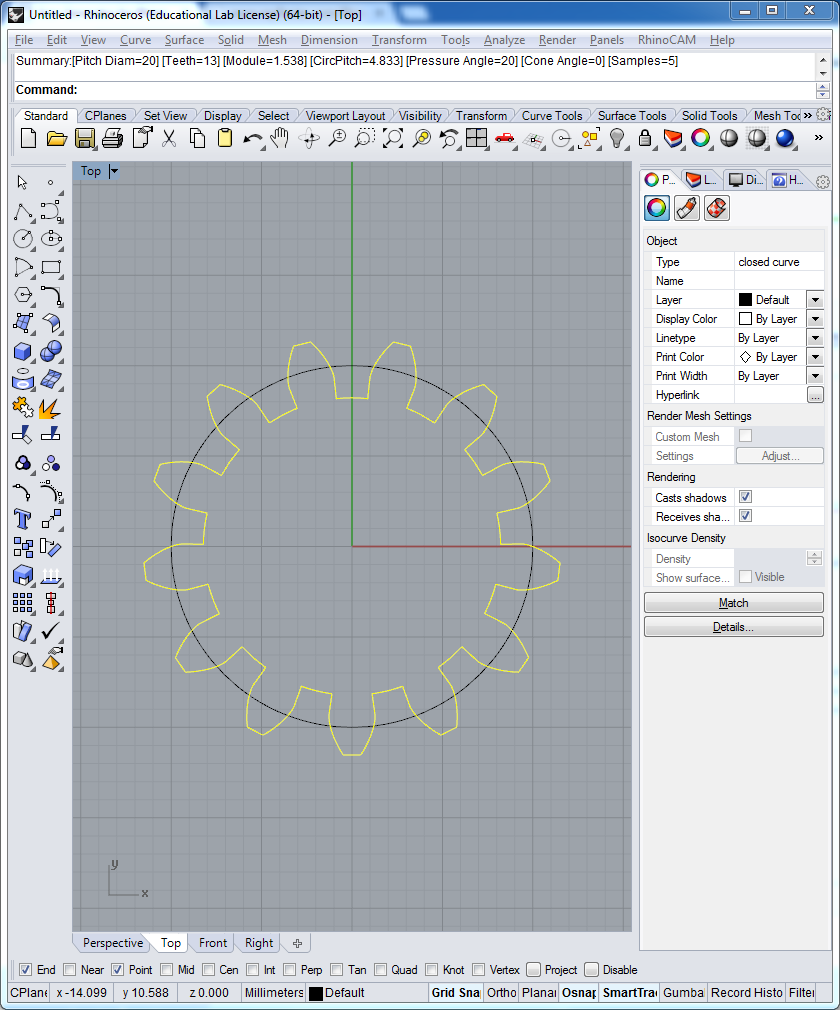

#ONLINE GEAR TEMPLATE GENERATOR GENERATOR#

The goal of this project is to provide a generator for lexical analyzers of maximum computational efficiency and maximum range of applications. Gear Lab Logo.Calibre has the ability to view, convert, edit, and catalog e-books of almost any e-book format. Cogwheel isolated icon graphic illustration. Bike Sprockets Vectors.Ĭog Wheel Banner Vectors. Group of connected gears vector isolated illustration. Working Together Illustration Vector.Īssorted Cogwheel Shape Set. We use cookies to make wikiHow great.Photos are now available on Vecteezy! Log in Facebook Loading Google Loading Civic Loading No account yet? Create an account.

#ONLINE GEAR TEMPLATE GENERATOR HOW TO#

To learn how to find a good wooden gear template for your project, keep reading! Did this summary help you? Yes No.

Finally, apply some wood varnish, and attach a handle to the gear. Next, drill a hole into the wood between each tooth on the template, and then use a band saw to cut out the gears. Then, glue the template to a piece of Baltic birch plywood, and cut around the circumference of the template with a band saw or jigsaw so you're left with a circular piece of plywood. To make wooden gears, start by printing a template of a wooden gear and cutting it out. Wooden gears might rely on your strength to crank a mechanism in order to accomplish tasks. Simple wooden gears are useful for low stress mechanical systems such as simple motors and various specialized systems. Gears are essential components in a plethora of mechanical systems. Updated: September 6, Reader-Approved References. Thank you to our community and to all of our readers who are working to aid others in this time of crisis, and to all of those who are making personal sacrifices for the good of their communities. We will continue to give you accurate and timely information throughout the crisis, and we will deliver on our mission - to help everyone in the world learn how to do anything - no matter what. Now, CNC users range from Fortune companies to the woodworker or machinist at home.During these challenging times, we guarantee we will work tirelessly to support you. Much of what we have learned is through actually working with children in classrooms. To my mind, the obvious solution to this tedious labour was to spend five times as much time and effort adapting the paper clock design so that it could be constructed from ply wood using the laser cutter at the space. The paper clock is a really nice project, but there is a lot of very fiddly cutting out of card with a craft knife and gluing together which is very fiddly and time consuming. This came about because I once started, but never finished making a clock out of paper. They show how to set up and do basic machining operations on a mill, lathe, drill press and other common shop equipment, but they do not include recommendations about cutting speeds or feed rates because students are expected to look up that information on their own. In fact, I was pretty sure I could cut out a gear faster on the bandsaw than most CNC hobby machines could.

You might want to bring out that beautiful grain even more. It would look beautiful that way, there is no doubt about it.

It's vital to use good plywood for the gears. The method I use to make the gears for the box joint jig is the same as for the gears for the wooden router lift, but I'll focus on the ones for the box joint jig in this article. You can click on any image in this article to get a larger view. So I figured I'd cover the topic of gear making in a bit more detail. How to make wooden gears This page also available in Spanish Some people are intimidated at the prospect of making their own wooden gears for the screw advance box joint jig.

0 kommentar(er)

0 kommentar(er)